As we know, in today’s challenging environment of industrial applications, the valves bear significant importance in terms of regulating and managing the flow of the fluids as well as other gaseous substances. Ever-increasing need for high-performance valve solutions due to industries’ need to increase the efficiency and reliability, and safety of processes. The suppliers of the industrial valves are among the leading players in this revolution as they seek to change to suit the market. This present article examines the way in which, to address customers’ needs, comprehensive valve solutions are designed and brought to the market space through innovation, which may be beneficial to B2B businesses in the system when it comes to dealing with suppliers.

Understanding Market Demands

The act of adapting is deeply inherent in the industrial setting due to innovation, policies among other market dynamics. In order not to lose the market, industrial valve suppliers should understand these demands and product accordingly. Supporting factors that have an impact on market requirements are: another step up in performance, quest for increased safety standards, and the necessity to work under more severe conditions.

Valves used in industries including oil and gas, chemical processing as well as power generation are in most cases exposed to high and fluctuating pressure, corrosive, and temperature environments. Further, the call for more efficient and less energy consuming has also impacted valves that have less leakages and losses. Through paying close attention to these market issues, suppliers can design new valves that will sufficiently meet these challenges.

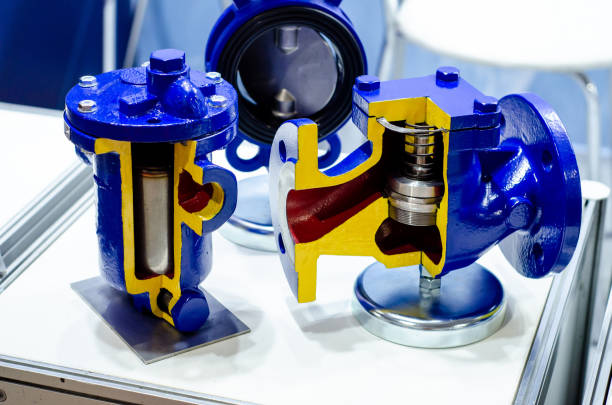

Innovation in Valve Design Valve design is the area that requires significant focus because it points to the innovation required to meet the market needs. Employing design technologies that include CAD and FEA designs, engineers are in a position to design the most efficient and reliable valve conformation. These tools help to reflect real-world scenarios and the performances of the valve designs and the materials used during constructions.

For example, new designs in ball valves have created low torque high sealing efficiency valves, indicated in process diagrams by the ball valve symbol where it has a high pressure capability. Through these design innovations, industrial valve suppliers are in a good position to provide their clients with high performing products with longer useful life despite working under harsh conditions.

Advanced Materials and Coatings

Yet another product development element that focuses on markets is the aspect of material choices where innovation has a big say. Identification of materials that should be used influences the reliability, efficiency and cost of the valve solutions. Progress in the field of metallurgy and material science has led to the availability of new wrought and cast alloys as well as new composite materials that can provide better control over corrosion, wear, and high temperature properties.

However, apart from the choices of the right material, the use of superior sur-face coatings offers another way of increasing the durability of valves. Chemical resistances include PTFE, ceramic, and nickel plating are commonly used to enhance the anti corrosive and anti abrasion cover. For industrial valves suppliers, it is beneficial to provide products with these materials and coatings as such enable them to supply companies in harsh conditions like marine, mining and chemical processing companies.

Smart Valve Technology

Smart integration of technology in valves is another trend that seeks to respond to the ever-rising market need for automation and better control of the valves. It is for this reason that smart valves have integrated sensors and actuators to control and monitor the flow rates, pressure and temperature within the valve. Some of these valves can interconnect with the central control systems where they can return information that can be of importance during the processes of improving productivity and estimating time of which the valves would require maintenance.

The application of smart valve technology provides a competitive edge for B2B businesses as it improves on operational efficiency with little to no downtime. Because industrial valve suppliers who provide smart valve solutions are able to better control processes and enhance the performances of the entire system. Since the IIoT is continuously advancing towards greater levels, the usage of smart valves will increase accordingly; therefore, the suppliers must innovate this product.

Customization and Flexibility

One of the biggest demands which are present in the market in the valve industry are the requirements for customization. No two industrial applications are identical and the capacity to deliver an application-specific valve is a key competitive advantage strategy. Valve customization can therefore take the following forms: change of valve size, material, actuation or design for enhanced operational features.

The suppliers of industrial valves that afford great degrees of latitude in valving designs should be favorably positioned to meet the needs of tough-conditions industries that are into special processes or operating under severe conditions. In this way, suppliers satisfy their clients’ needs and develop loyal cooperation with them, knowing that they will receive products of the needed quality from a trustworthy contractor.

Commitment to Quality and Compliance

Another factor that cannot be ignored and which defines valve production is quality and compliance especially when working with critical processes. In order to satisfy these expectations, suppliers of industrial valves require stringent quality management procedures and guarantee that valves produced are standard with corresponding quality accreditation and rules.

Testing through certified laboratories, superior inspecting techniques, and Standards API, ASME, ISO must be employed as measures towards achieving the quality of valves. For the B2B businesses, dealing with suppliers that consider quality and compliance to ensure that only the best performing and safe products are delivered to the company as needed in specific applications.

To supply the market for valves, there has to be a focus on fundamental areas that include innovation, quality, and product differentiation. This insight enables the industrial valve suppliers to design valves that effectively fulfill the diverse requirements of clients, improve performance, reliability, and safety. Starting from valves and materials, through integration of smart technologies and strict quality control these suppliers know how to meet the needs of modern industries. In evaluating B2B scenarios, it makes sound business sense for B2B buyers to engage suppliers who have defined and optimized these competencies to unlock the type of valve solutions that can unlock business success.